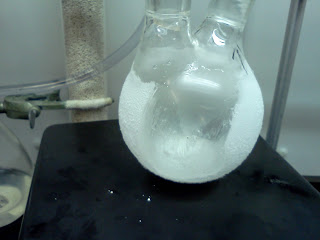

(at beginning of reaction)

(after reaction was completed)

We vacuum-filtered the solid out of the liquid and tested the liquid in the IR. We didn't really get any peaks with the liquid, so we decided to test the solid. There were a couple of small yellow crystals in the dark brown solid which led us to believe that our desired product was contained in the solid.

We had the idea of extracting the solid with methylene chloride four times, and we did this by mixing all of the solid into about 20 ml of methylene chloride and then vacuum-filtering out the remaining solid that hadn't dissolved in the methylene chloride. We added the remaining solid to another 20 ml of methylene chloride and repeated the process twice. We could tell that it was working because the methylene chloride turned yellow as we did this, and the amount of solid lessened with each extraction.

We added a boiling chip to the extracts and reduced the volume until there were only about 5 ml left in the hopes that this would give us more intense peaks. When we tested this liquid in the IR, there were very small peaks that correlated almost exactly to the literature values for this complex (we had 1954 and 1862 cm-1 while the literature values were 1954 and 1862 cm-1). We could then consider our final synthesis a success!!

For the last week of the semester, we worked on putting all the aspects of our labs and our project together so that we could present them in one portfolio. Overall, we had an awesome semester! We learned a ton of new lab techniques and worked together to make our project a complete success, with 6 out of 6 complexes synthesized. We got to see a variety of different inorganic compounds (all pretty colors, of course!) and we developed a new appreciation for organometallic compounds such as our Cr Arenes. We in Purple Chrome wish that you could have as much fun reading this blog as we had doing the experiments we wrote about!